Search Results for: Blog

Bridge Solutions Group partners with Ultra Commerce to provide intelligent fulfillment

June 12, 2020 by Doug Brochu

U

ltra Commerce, provider of a global commerce platform with deployment accelerators, and Bridge Solutions Group, a consulting firm that specializes in intelligent fulfillment solutions have announced a global partnership.

Bridge Solutions Group and Ultra Commerce will work together to provide end-to-end commerce and distribution solutions for retailers, brands, and B2B organizations.

“This partnership with Ultra Commerce will enable us to provide a seamless commerce, order management, and warehouse management experience for our customers. This will include online stock availability, inventory visibility across the enterprise, a single view of orders across all channels and business units, and optimized fulfillment from any location.” said Doug Brochu, CEO of Bridge Solutions Group.

For more information on the combine ecommerce and fulfillment solutions, Contact Us today.

Filed under: Blog, Conferences, Supply Chain

B2B Marketplace: Why you need one, and 7 steps to get there

September 19, 2018 by The Bridge Solutions Group Team

A B2B marketplace lets you sell more without having to own the inventory.

The June 2018 release of Gartner’s Magic Quadrant for Digital Commerce listed five strategic assumptions. Number two was interesting: “By 2020, more than 50% of online sellers will either list their products on marketplaces or sell third-party products on their core commerce sites.”

That’s only two years from now. Do you sell your products on a marketplace like Amazon or Walmart? Many vendors do. However, not nearly as many have a marketplace of third-party products on their own ecommerce sites. But it’s a growing trend, even for B2B commerce.

In fact, Amazon Business revealed in a September 2018 blog post that third party sellers make up more than 50% of their $10 billion in global sales.

In other words, Amazon Business doesn’t own the inventory for over 50% of sales. They just take the order, and route it to the appropriate third-party vendor for drop ship. With a marketplace, you could do this too. A marketplace lets you offer an expanded assortment of products that compliment your core inventory, so you can drive top line growth at a high profit, and without the expense associated with inventory. Imagine not having to own every product you sell. What could you do with that cash?

A lot, no doubt. But the first step on your journey to that enviable position, is to set up a marketplace. Below are the 7 key steps to success:

1. Implement a marketplace platform

There are several off-the-shelf options available, or you may choose to build your own, but you’ll need a way to manage your vendors and their products and where you want them to display on your ecommerce site.

2. Onboard vendors and their product catalog

There are two ways to add a new vendors and products to your marketplace. The first, is to provide a portal where vendors input or upload marketplace item information directly. In this case, the vendor will provide item or category recommendations. The second, is using an on-boarding provider with a network of suppliers to help you onboard new vendors quickly and efficiently so you can start selling new products in a matter of days. The advantage here is that the on-boarding provider can quickly load product information with the correct and complete item data. In fact, some of them can even make vendor and product recommendations based on aggregate sales data from across their supplier network. But even if you can outsource onboarding there are some internal considerations too.

For example, you’ll want to define who will determine which products to offer in your marketplace. Will you have separate team select the assortment to be sold on your marketplace? Or will your category buyers be responsible for selecting complementary products to include in your marketplace? Addressing (and communicating) this decision up front will save a lot of conflicts in the future.

3. Integrate vendor pricing, promotions, and inventory availability updates with your ecommerce platform

Once the catalog is loaded, you’ll need additional product information such as pricing, promotions, and inventory availability, and you’ll need a mechanism for regular updates. This lets you display products from the newly loaded catalogs on your ecommerce site, and always display accurate stock information so you can avoid canceled orders.

4. Determine which fulfillment options best suit your business

Your marketplace may offer several fulfillment options to the customer. The most common is to drop ship the product(s) to the customer’s address from the vendor. However, if the marketplace item is part of a larger order, some marketplace owners prefer their third-party vendors to ship the merchandise to them for order consolidation. That way the customer receives a single package. However, this may also delay delivery, so you’ll need to think about what works best for your customer base.

5. Capture marketplace orders and send them to the vendor

If a customer places an order that includes both owned inventory and marketplace items, you’ll need the ability to split that order and send the marketplace line items to the appropriate vendor, for a seamless customer experience.

6. Track status

Just because items are shipped from a third-party vendor, doesn’t mean customers won’t expect status updates from you. Make sure you define a process to provide marketplace shipment status tracking to customers, both online, and via email and/or text. Remember the customer is making the purchase from your brand.

7. Complete the financial transaction

Once the product has been shipped, the order needs to be reconciled financially. After you receive shipping confirmation from the vendor, you charge the customer. Then you withhold a predetermined percentage of the sale as a commission, and pay the remainder to the vendor.

In summary, a B2B marketplace is a new means to drive top line growth. And with more and more products and services designed to accelerate marketplace deployment, the opportunity to expand business via the marketplace has never been better. If you’d like to learn more about launching a marketplace, please Contact Us.

Filed under: Blog, Omnichannel, Supply Chain

Ship from Store Change Management: 15 questions you’ll need to answer

July 16, 2018 by The Bridge Solutions Group Team

Where will shipping materials be stored? Who will train store associates how to package fragile items so they don’t get damaged? These are just some of the change management considerations for Ship from Store.

A retailer’s greatest liability is their inventory. It represents a huge capital investment. One on which the return must be maximized. Yet competition in retail is fierce. And not just because of downward pressure on item prices. Rivalry now includes the cost of delivery, consumer expectations for fast delivery, and their unwillingness to pay for speed. Thanks Amazon. So, what can multi-channel retailers do?

In the quest to compete with Amazon’s fast delivery speed, stores are a key advantage. Ship from Store, where ecommerce orders are shipped from a local store to the customer, is one of the fastest growing trends in retail. Stores do double duty as mini Distribution Centers (DCs). And it’s not surprising. With at least 80% of their inventory in the stores, at a location so close to customers, it is a great way for retailers to deliver faster, and for less money. Think about Walmart in the United States…

Their 4,700 stores are located within a ten-mile vicinity of 90% of the U.S. population. This means delivery from a Walmart store to a customer would be a fast, and easy way to reduce shipping costs. Now, not all retailers have 4,700 stores. But if they have more stores than DCs, there are still many advantages to Ship from Store. For instance:

- Delivery times can be reduced without the high cost of expedited shipping from a DC hundreds of miles away

- Store inventory can be utilized to fulfill online orders, which can reduce the amount of inventory held at a DC

- By using slow moving inventory at a store to fulfill online orders, markdowns can be avoided or reduced, and

- By leveraging store inventory, retailers can achieve a 10-20% revenue increase simply as a result of reducing the number of lost orders due to out of stocks.

But the complexity of Ship from Store should not be underestimated. Implementation requires store associates to learn new processes and skills. And like any other omni-channel fulfillment initiative, preparation is key. So here are some change management questions to consider:

- Who and how will the store receive the order? Is this a store or backroom function?

- Where will ecommerce orders be staged, packaged and held in the store?

- Where will shipping materials be in the store?

- Who will train store associates how to package items for shipping?

- Will they require special training for fragile items so they don’t get damaged in transit?

- How will the store print shipping labels?

- Will the store pick items during store hours or off hours?

- In the store, will there be specific associates responsible for pick, pack and shipment?

- Will the store associate process the shipment confirmation via the Point of Sale system? Online? Via a mobile device?

- How many orders can the store handle per day? Will additional labor be required? What is the anticipated volume increase during peak season or promotions?

- Will the store be shipping merchandise through, USPS, UPS, FedEx, Uber, or associates? Will it change by location? Delivery address? Customer preferences? Time the order was placed? Carrier pickup time?

- Who is responsible for the shipping process and cost? Will the shipping expense be charged to the store or online for compensation/bonus calculations?

- How will packages be sorted for different carriers?

- If items in single order are being sourced from multiple locations, are stores going to consolidate orders via the DC and/or store transfers? How will store associates know which items belong to which order?

- Will additional information, return labels, or promotions be included in the shipment?

Ship from Store is the most complex of all store fulfillment. Stores were not designed to be distribution centers. They were designed for cash and carry. But it’s a great option to leverage all inventory within the omni-channel journey. And with ‘Ship from Store’ you can take full advantage of your entire store network to fulfill online orders. To learn more about Ship from Store change management, please Contact Us.

Filed under: Blog, Omnichannel, Supply Chain

In-Store Pickup Change Management: 35 questions to get you started

June 27, 2018 by The Bridge Solutions Group Team

When she gets to the store to pickup her online order, will the pickup experience inspire additional purchases?

57% of online shoppers said they had picked up an online order in a store in the last year according to results of a study published in August 2017. And in-store pickup is a great way to drive traffic into stores. In fact, 71% of customers will make an additional purchase while in the store.

But if your customers have an unsatisfactory in-store pickup experience, there’s a good chance they’ll skip the additional purchases, which will impact the return on your Buy Online Pickup In-Store (BOPIS) investment. So, in this article, the second in a series that started with Buy Online Return in Store: 15 change management questions to consider, we’ll cover some change management questions that will help you craft a high quality pickup process.

To make it easier, we’ll align the question with the 3 different approaches to Buy Online Pickup In-Store, in order of complexity:

- Ship to store from Distribution Center (DC)

- Drop ship to store from third party vendor

- Pick order from store inventory

Ship to Store from Distribution Center (DC)

This is the simplest model. Orders are shipped directly to store, from the DC, pre-labeled with the customer’s information. Store associates do not have to pick orders, so business disruption is minimized. Key change management questions include:

- In the DC, how will warehouse employees package items being shipped to a store for pickup?

- Where will store pickup orders be staged in the DC?

- How will store associates know which inventory is designated for a customer? Will they be labeled so they’re easily identifiable?

- Will they be shipped to the store with store replenishment orders? Or separately?

- Where will store associates stage store pickup orders once received?

- How will customers know where to go to pickup their order in the store? What signage will stores need?

- Will the store associated process the pickup confirmation via the Point of Sale system? Online? Via a mobile device?

- How many pickup orders can the store handle per day? Will additional labor be required? What is the anticipated volume increase during peak season or promotions?

- How do you handle abandoned orders (those not picked up by the customer)?

Drop ship to store from third party vendor

Drop shipping is a popular way for retailers to provide an expanded assortment without owning the inventory. Drop ship to store offers this same inventory expansion, but with the added benefit of driving store traffic. It works particularly well when the drop shipped item is part of a bundle of products ordered by a customer, for example:

- Accessories to complement an outfit

- Custom helmet to go with a new bicycle, or

- Specialized accessories for a new mobile phone or computer

This way, the customer visits the store once and receives all their items at the same time. But to successfully receive in-store pickup orders from multiple sources (which may have inconsistent packaging and labeling) requires some additional thought. Change management questions for this use case include:

- How should third party vendors label orders so they’re easily identifiable? Can this be standardized?

- If the items are part of a larger order that needs to be consolidated, how should this be indicated?

- Where should store associates stage items awaiting consolidation?

- How will store associates be notified when all items in an order have arrived and are ready to be consolidated?

- How do you handle abandoned drop ship orders (those not picked up by the customer)? Should they be returned to a single location for sorting? Or shipped directly to the drop shipper?

Pick order from store inventory

This is where things get tricky. Why? Because, while inventory accuracy in a well run DC is usually good, stores are a different matter.

Inventory moves from the backroom to selling floor, rides in carts, is abandoned in fitting rooms, or placed on random shelves by customers. And whether your revenue is $200 million or $12 billion, the number one challenge when fulfilling orders from store inventory, is inventory accuracy. Without it, you’ll have canceled orders which result in customer disappointment, and lost sales. So when you start preparing to pick orders from store inventory, consider how best to achieve the inventory accuracy you’ll need to ensure success. Some important initiatives to consider include:

- Implement real-time (or near real-time) sync of Point of Sale (POS), Order Management, Warehouse Management, eCommerce, and ERP systems – if not for every SKU, at least for high velocity SKUs.

- Assign ‘Safety Stock’, or a number of units of a given item below which an ecommerce order is not sent to a store to fulfill.

- Have store associates conduct cycle counts of store inventory, just like in a warehouse.

- Using RFID to track inventory.

Other change management questions you’ll want to address are:

- How will store associates be notified that an order is ready to pick? Via the POS? A mobile device? Printed pick ticket?

- What system will store associates use for picking?

- Can the system provide the item location (do you have standardized store planograms)?

- How will associates pick orders? By product? By order?

- Will associates pick orders from the floor, the backroom, or both?

- If an item is out of stock, and a store associate enters a ‘no pick’:

- Does the system send an alert to check in the backroom?

- Will inventory availability be updated to prevent future customers from ordering this out of stock item as well?

- What is the planned placement/setup of merchandise that is pending pickup? How will it be organized?

- How will store associates indicate an order is ready for pickup?

- How will the pickup be processed in the store? Via POS? Mobile device?

- How will customer communications be managed? (e.g. Order ready for pickup, Order not picked up, or Order can’t be filled)

- What is the escalation process for orders not picked? What alerts are needed and who receives them?

- Do you want to limit the number of BOPIS orders that can be fulfilled by a store within working hours?

- How do you handle abandoned orders (Customers Not picking after the Order is ready for Customer Pickup)? Will the order be canceled and the items restocked after a certain period? If so, what is the process for canceling an order due to no pickup?

- What is the current associate utilization in the stores? Will additional labor/time and dedicated resources be required? What is the maximum number of orders a store can process per day?

- If inventory is not available, do you want to provide substitutions? If so, how will store associates ask a customer if a substitution is ok?

- Do you want include display stock in the ‘available inventory’ for pickup orders? If not, how will you exclude that inventory systematically?

- Do store associates scan inventory when moving it from the backroom to the floor to ensure inventory location is accurate?

- What cycle count/inventory adjustment capabilities exist in stores? Should store associates do an item count each time they pick an order?

- How well-established are the lines of communication between the e-commerce and store teams relative to promotional activity (e.g. how will stores be notified of upcoming online promotions that will impact BOPIS volume?)

- Who will determine safety stock levels? Store managers? Planning and allocation? Supply chain?

- What metrics will be used to measure in-store pickup success? Orders processed per store? Orders processed per associate? Pick turnaround time? Order accuracy? How will you incentivize store associates to pick orders quickly and accurately?

As you can see, in-store pickup has some complexity. But it’s a great stepping stone on your journey to offering ‘Ship from Store’ after Buy Online Return In-Store. And with ‘Ship from Store’ you can fully leverage all your inventory across your entire store network to fulfill online orders. This let’s you minimize markdowns and reduce inventory carrying costs. In the next article in this series, we’ll look at some Ship from Store change management questions. In the meantime, if you’d like to learn more about BOPIS change management, please Contact Us.

Filed under: Blog, Omnichannel, Supply Chain

Buy Online Return In-Store: 15 Change Management Questions to Consider

June 11, 2018 by The Bridge Solutions Group Team

If she can’t return her online purchase in-store, she may not buy it at all.

The retail race for digital supremacy is on. While so many have filed for bankruptcy protection, or closed stores, the trend is clear. Retailers who invested in tech early are doing well. Those who didn’t have struggled to keep their customers excited and engaged with their offerings.

And what’s number 3 on the list of ‘Top 10 Technologies for 2018’ according to the 2018 RIS/Gartner Retail Technology Study? One of our favorites: In-store pickup/return. But technology is just a tool. And while multi-channel customer experiences require a robust, well integrated technology stack, it is not enough by itself.

Yet all too often retail technology implementation plans fail to allocate enough time and resources to another essential component: Change management. But without good business processes, and employee training and engagement to support your technology, you can’t achieve maximum return on your digital investment. According to the study, “Change Management” was ranked number 6 of the ‘Top obstacles over the next 18 months’. And we have seen this first hand.

Retailers have bought software, underestimated the change management involved, then shelved the software (i.e., they paid for it, but didn’t implement it), because they failed to scope out the appropriate level of change management required to make the project a success before making their technology investment. What a waste!

We’d like to help you avoid that situation. So, in this series of articles, we offer you some questions to consider when designing your change management program.

Buy Online Return In-Store (BORIS) Change Management Questions

- What is your company’s high-level goal for BORIS, and how does it fit with your strategic vision?

- What is the ideal customer experience for returns?

- Why is a positive return process so important to long term customer loyalty?

- How will your BORIS policy and procedures be developed? Can you get store associate buy-in early in the process?

- Where will returns be processed?

- What signage will be needed in stores to guide the customer?

- How should returns be processed?

- How should exceptions be handled?

- What constitutes ‘return abuse’? And how should it be handled?

- Where will returned items be staged before they’re placed back on the selling floor?

- Are there different processes for different types of merchandise?

- Which stores will you use for testing to develop a baseline for average number of store transactions, revenue, and labor?

- What metrics will be used to monitor BOPIS? What does success look like?

- How will desired behaviors be rewarded?

- How should store associates provide feedback on the process, or submit suggestions for improvement? And how will they know their feedback has been processed?

As you can see, there’s a lot more to ‘Buy Online Return In-Store’, than just connecting your eCommerce and Point of Sale system with an Order Management System. Next in our series, we’ll look at In-Store Pickup Change Management: 35 questions to get you started. In the meantime, if you have any questions about returns change management, feel free to contact us.

Filed under: Blog, Omnichannel, Supply Chain

The New Retail CX: A Shared Experience (SX) across Retailer and Brand

May 9, 2018 by The Bridge Solutions Group Team

The new Retail CX is a Shared Experience: a blend of the customer’s Retail and Brand experience.

In today’s market, Retailers must provide a superior Customer Experience to survive. They continue to fight to attract and keep more customers by making them feel special. Armed with data analytics, marketing insights, and artificial intelligence tools, retailers constantly tweak their messaging and pricing to attract customers and increase basket size. But one could argue that how you SERVICE your customers is just as important, possibly more so, than how you attract them. The days of personalized customer relationships and doing ‘out of the ordinary’ events are returning.

But, hasn’t retail always been about the customer? Isn’t the customer #1 or king? These questions are easy to debate in today’s world where technology has replaced interaction. What customer doesn’t use technology in their retail experience. Many retailers have invested in sales associate customer assistance devices. These hand-held units provide store associates with product and customer information. The value of sales associates and their necessity may be changing, but as new technology like Amazon Go becomes more affordable the game may change.

What is a Shared Experience?

A “Shared Experience“, SX, between manufactures, retailers and customers is the evolution of Customer Experience. Technology is designed to connect, communicate, and share. These three capabilities will continue to change the game. Imagine if the manufacture, retailer and customer were willing to fully integrate this concept. The retailer buys from the manufacture and once the delivery is made the relationship shifts from the manufacturer to the customer. The manufacture, if they are correct, may be lucky enough to get another order. The three are never connected in the experience.

SX for Out of Stock Recovery

Silos don’t work, and providing a shared experience is hard. Manufacturers make what retailers or customers request. The shipment is made, invoices submitted, and the manufacturer is off to the next season. The retailer is challenged to have the item in stock, at the correct price and size. At best, they may be able to achieve this 80-90% of the time. The latest trend is to share the customer’s data for the next season. But historical data doesn’t always predict future trends.

In a perfect world, the retailer would have access to every item and size from the manufacturer. This model is conceptual, but possible. Think of how often you have been at a store looking for a particular branded item that is not in stock. The brand manufacturer and the retailer generally lose the sale. If a store doesn’t have an item available, why can’t the retailer order it from the manufacturer and have it sent from the manufacturer to the customer’s home or nearest store? Since out of stocks are a top influencing factor, dissatisfaction and frustration destroy brand loyalty. In fact, studies have discovered that 91% of customers don’t want to engage with a business anymore once they’ve had a bad experience with it.1

Shared Experience Agreements

The technology for SX out of stocks is available, but the manufacturer and retailer struggle with who owns the customer, and the revenue. Silos get in the way of taking care of the customer and the experience falls apart. The SX fails because of the lack of an integration, agreement and process. Manufactures who are willing to satisfy the customer in this process will increase brand loyalty. The store made the sale and the manufacture fulfilled the sale. Revenue is generated versus lost for both parties.

In the SX world, the manufacture, retailer and customer all win.

Source:

1. “The Out of Stock Problem and How To Approach It”, Streetspotr August 2017

Filed under: Blog, Supply Chain

Forbes: Best Management Consulting Firms for 2018 – IT Implementation

April 25, 2018 by The Bridge Solutions Group Team

For the third year in a row, Forbes has named Bridge Solutions Group one of the Best Management Consulting Companies for IT-Implementations. We’d like to extend an enormous thank you to all our customers who completed the survey. We are honored yet again!

For the full list of firms see:

https://www.forbes.com/best-management-consulting-firms/list/

Filed under: Blog, Conferences, Supply Chain

Case Study: Jenkins for OMS Code Branch Management

April 23, 2018 by The Bridge Solutions Group Team

Business Challenge

Jenkins is a popular open source Continuous Integration (CI) and Continuous Delivery (CD) solution. A customer was using Jenkins to manage their front-end eCommerce development, but was not using it to manage their IBM Order Management (OMS) development projects, instead they were using Rational Team Concert (RTC) as their code repository.

As a result, they were unable to run multiple Order Management development project simultaneously, because they didn’t have a good way to manage their code base, and deployment to different environments.

Solution

Bridge Solutions migrated the customer’s Order Management code base from RTC to Jenkins, and enabled integration between Jenkins and Bitbucket to enable an instance level code management and build mechanism. The project was completed in 2 months, which included testing. This allowed them to have multiple code branches, not just a single branch, so they could support multiple development projects simultaneously.

Key Benefits

- The Jenkins platform will enable the retailer to have multiple branches of code base and do parallel development on multiple projects. This will ease and reduce risk in builds in different environments.

- The customer was able to decommission RTC, and save money.

- The ability to respond to build issues early. Jenkins sends emails to specified recipients whenever a certain important event occurs, such as:

- Failed build

- Unstable build

- Successful build after a failed build, indicating that a crisis is over

- Unstable build after a successful one, indicating that there’s a regression issue.

- Jenkins is an open source tool with support from its community and has more than 1000 plug-ins to make improve development efficiency.

- It is easy to create a new Jenkins plugin if one is not available for a specific use case.

- Because Jenkins is written in Java, it can be portable to almost all major platforms.

For more information on CI and CD solutions for Order Management, please Contact Us.

Filed under: Blog, Supply Chain

Amazon Go: A Different Kind of Line

February 5, 2018 by The Bridge Solutions Group Team

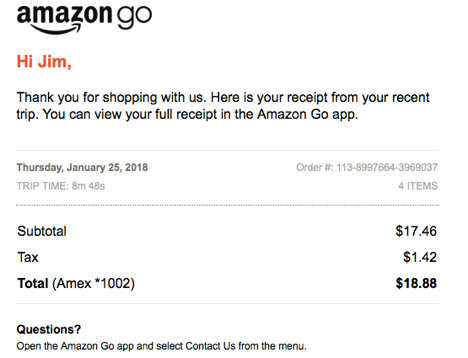

Amazon prides itself on the customer experience and Amazon Go delivers, but in a different way. The line is no longer at the register but is at the door! The Amazon Go store has a capacity limit and sales associates restrict how many customers may enter. Even with the line at the door, the process was very quick and seamless.

Customer convenience is at an all-time high and no one likes waiting for a cashier to scan their items. This process is so simple at the Amazon Go store. You simply scan your bar code upon entering, and place items in your bag or hand. Leave the store through the designated scanner and the transaction is complete.

I tried to put an item in my jacket, pick up an item and replace it on the shelf at a later time and re-enter with items purchased. But I failed to trick the system. Each item was correctly accounted for on my receipt. This seems to be shrink proof!

Filed under: Blog, Supply Chain

For FREE insights into how to improve your supply chain, simply enter your contact information for access to our entire library of eBooks, whitepapers and data sheets.

For FREE insights into how to improve your supply chain, simply enter your contact information for access to our entire library of eBooks, whitepapers and data sheets. You'll be missing out on access to hundreds of pages of supply chain industry ideas and insights that will make you look great in your next meeting.

You'll be missing out on access to hundreds of pages of supply chain industry ideas and insights that will make you look great in your next meeting.